Predictive Maintenance AI System

Built an AI system that predicts equipment failures before they occur, reducing downtime by 75% for a major manufacturing client.

Overview

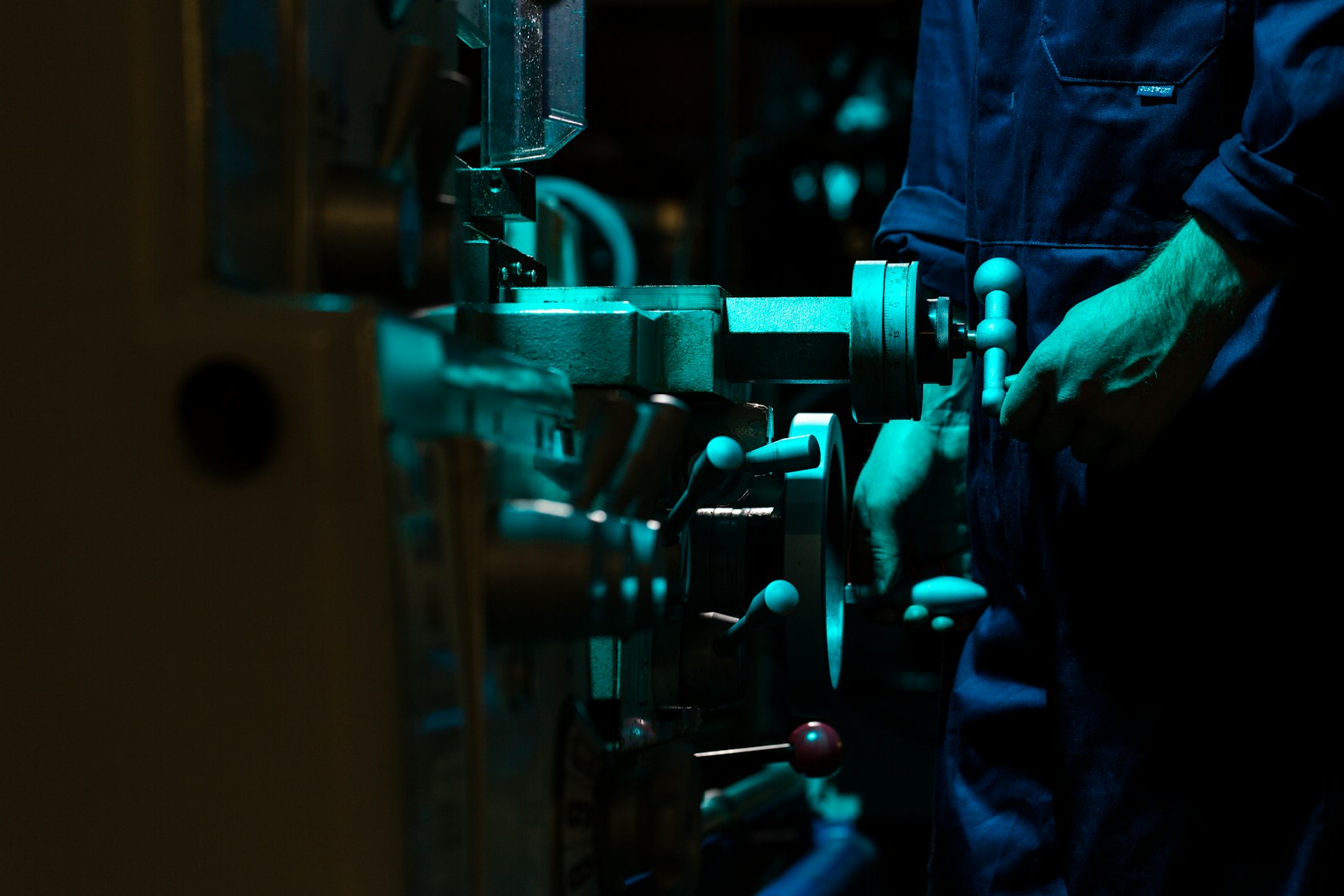

A heavy industry manufacturer was experiencing significant losses due to unexpected equipment failures and production downtime. Traditional maintenance schedules were inefficient and often resulted in either premature part replacement or catastrophic failures.

RL SMART Solutions developed a predictive maintenance AI system that:

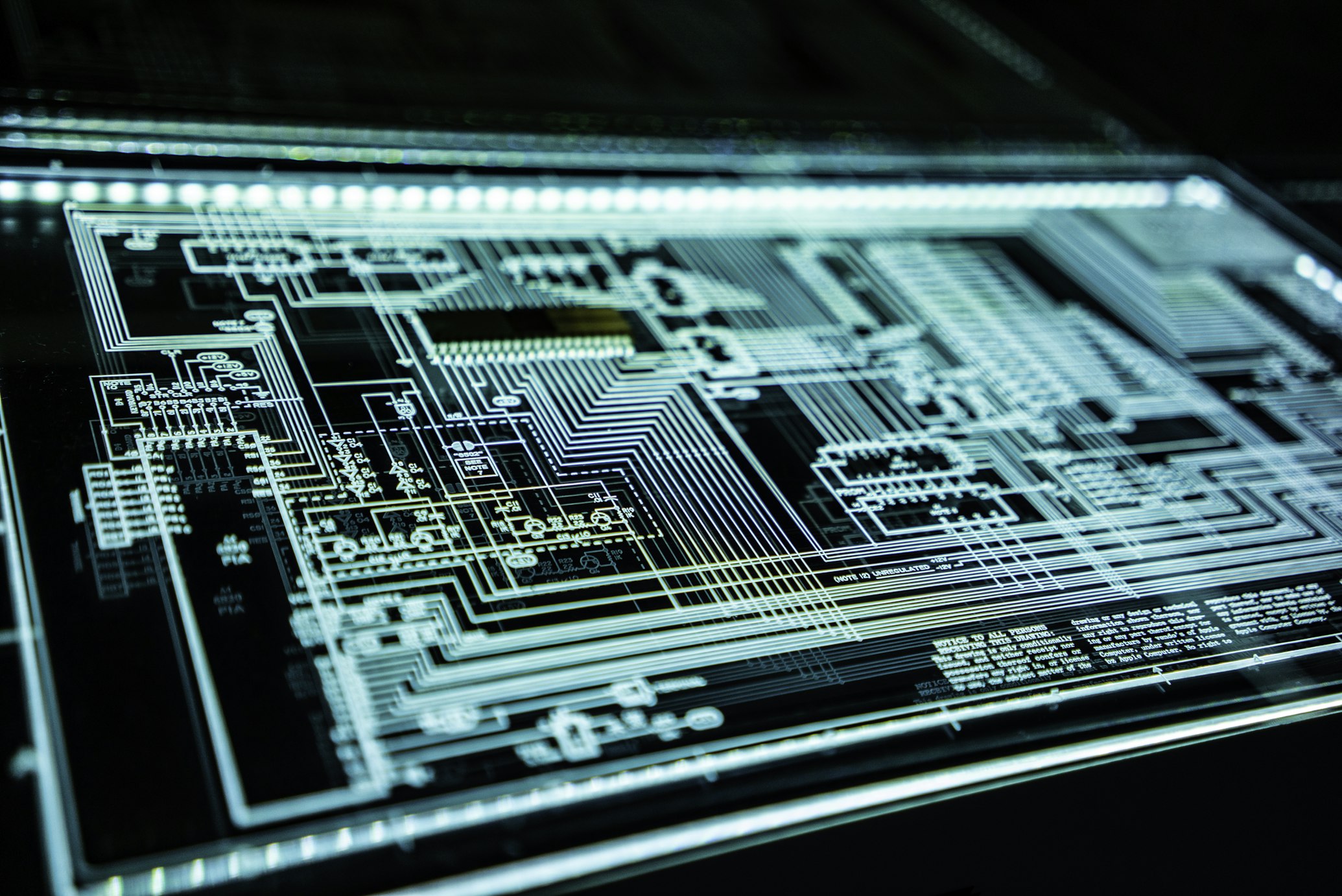

- Collected data from IoT sensors installed on critical equipment

- Analyzed patterns and anomalies using machine learning algorithms

- Predicted potential failures days or weeks before they would occur

- Provided maintenance recommendations with priority levels

- Generated comprehensive reports for maintenance planning

The implementation resulted in a 75% reduction in unplanned downtime, 40% decrease in maintenance costs, and 25% extension of equipment lifespan. The system paid for itself within the first six months and has become a critical component of the client's operational strategy.

Gallery

Project Details

- AI Development

- IoT Integration

- Predictive Modeling

- Systems Integration

Related Case Studies

AI-Powered Customer Insights Dashboard

Created an AI analytics platform that processes customer data to provide actionable insights, increasing customer engagement by 35%.